Chongqing ITCC Super Tall

Image courtesy of KPF

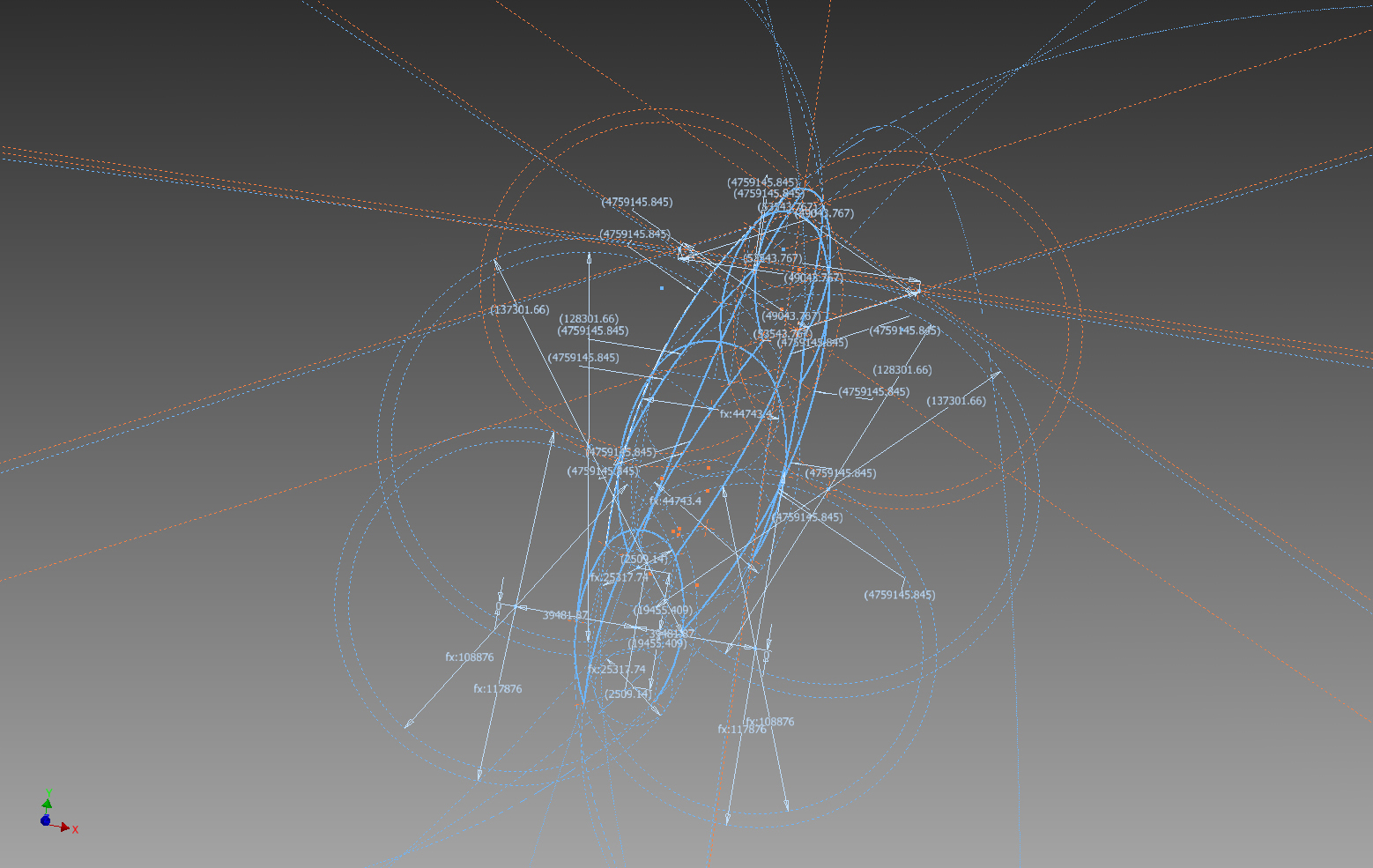

Chonqing International Trade and Commerce Center is a mixed-use development consisting of three towers, linked together at the base by a retail podium. The tallest tower housing office spaces and hotel is 468 meters tall which is placed centrally along the site anchoring the project and creating a focal point. The taller two towers are comprised of massing geometry that curves in multiple directions, all derived from tangential arcs in both plan and section, sweeping along various profiles. All the radial geometry is driven by a parametric wire-frame model where constraints are built-in to preserve the relationships between the geometric profiles.

Image courtesy of KPF

Image courtesy of KPF

The concept for the façade is derived from the Chinese calligraphy character known as “double happiness” which historically is a symbol used in traditional ornament design. This symbol is echoed in the façade pattern. Each pattern spans four stories tall, and seven modules wide, consisting of 28 unique façade panels. Each of these panels are color coded and labeled as the pattern repeats itself throughout the building. The inherent nature of the double curved geometry of the massing allows the pattern to shift creating a moray effect.

Image courtesy of KPF

Image courtesy of KPF

Image courtesy of KPF

The irregular shape of the buildings required deviation from the standard conventions of architectural documentation practices. The entire façade was unrolled onto a flat plane, the length of each edge was documented along with the corner angles and panel twist value. Every panel was given an ID value to locate the panel in space and identify its position within the double happiness pattern. All this data is cross referenced in a spreadsheet which allows for ease of quantifying and tracking purposes. This data set is proved to be vital during the construction administration process, allowing cross reference of shop drawings with ease. The custom algorithms to execute these tasks allow the design team to focus on design and less on coordination.

Image courtesy of KPF

Image courtesy of KPF

Due to the staggering nature of the pattern, some of the vertical stack joints intentionally do not align with the joints below. Cases such as these earned the nick name of “bird’s beak” conditions. These conditions are all analyzed and taken into consideration when designing the details for the stack joints. The benefits of custom algorithms allow the empower the design team to be better informed about the design and to demystify the complexity of the project.

Image courtesy of KPF